AlpRMS Billet rhomboidity measurement system

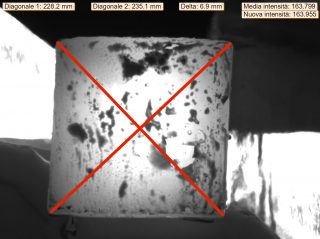

AlpRMS is an innovative system based on Machine Vision aimed at identifying the presence of the characteristic rhombic distortion in billets. By automatically calculating dimensional values, through image processing, it can provide timely alerts and notifications in case of a billet’s non-compliance.

MEASUREMENT OF RHOMBIC

DISTORSION IN BILLETS

MACHINE VISION TECHNOLOGY

AND COMPREHENSIVE

USER GRAPHIC INTERFACE

AlpRMS automatically and continuously monitors the geometry of the billets, identifying any rhombic distortions and thus enabling prompt adjustments of the casting parameters as needed. The system allows for the constant verification of the process, improving production efficiency and attaining optimal workflows. In addition, the ability to perform immediate checks at the entrance of the cooling bed reduces the number of non-compliant billets and proves to be of strategic importance in plants that use billet welders with specific limits of work.

The system’s user interface allows the operator exhaustive control over the data processed by the software by displaying the image of the billet, all the applicable parameters and each data relevant to the product, such as the casting identifier, the billet ID, the line number, the steel brand and the rhomboid’s delta. Traffic-light like, red and green, coloured alerts immediately show the outcome of the product’s screening indicating whether the billet is compliant.

Completing the key features of the system are data-logging and image storing dedicated facilities and the regular release of statistical reports.

DISTINCTIVE FEATURES

Precision

High-Quality images and accuracy down to a tenth of a millimitre

User-friendliness

No MV knowledge required

Live alerts

Immediate notification of non-compliant products

Interfacing

Real-time exchange with plant automation and system surveillance

Data logging

Data and image storing on a dedicated database

Modular design

It can use up to four cameras

Ease of installation

No complex assembly is required

Operating Safety

No specialist presence required in hazardous areas